Industrial Scales vs. Regular Scales: What’s the Difference in Performance?

Industrial Scales vs. Regular Scales: What’s the Difference in Performance?

Blog Article

Why to Choose Industrial Scales for Accurate Weight Dimension in Numerous Industries

In an age where accuracy is critical, the selection of commercial scales for precise weight measurement plays an essential duty across varied fields. These scales not just enhance functional efficiency yet additionally make certain compliance with regulative standards, influencing every little thing from production to delivery.

Relevance of Accurate Weight Measurement

In the world of commercial procedures, the value of accurate weight measurement can not be overemphasized. Accurate weight dimension is foundational throughout various markets, affecting both operational efficiency and product top quality - Industrial Scales. It acts as a crucial consider supply management, making sure that materials are adequately represented, thereby lessening waste and decreasing costs

In manufacturing, exact weight dimension straight influences manufacturing procedures. Abnormalities in weight can result in low-grade items or excessive resource allotment, impacting general productivity. Additionally, in markets such as drugs and food production, adherence to strict weight requirements is important for governing compliance and consumer safety and security.

Furthermore, accurate weight dimensions facilitate reliable logistics and supply chain management. Properly considered shipments make certain that transport expenses are enhanced and that supply degrees are maintained precisely, thereby stopping stock lacks or overstock circumstances.

Kinds of Industrial Scales

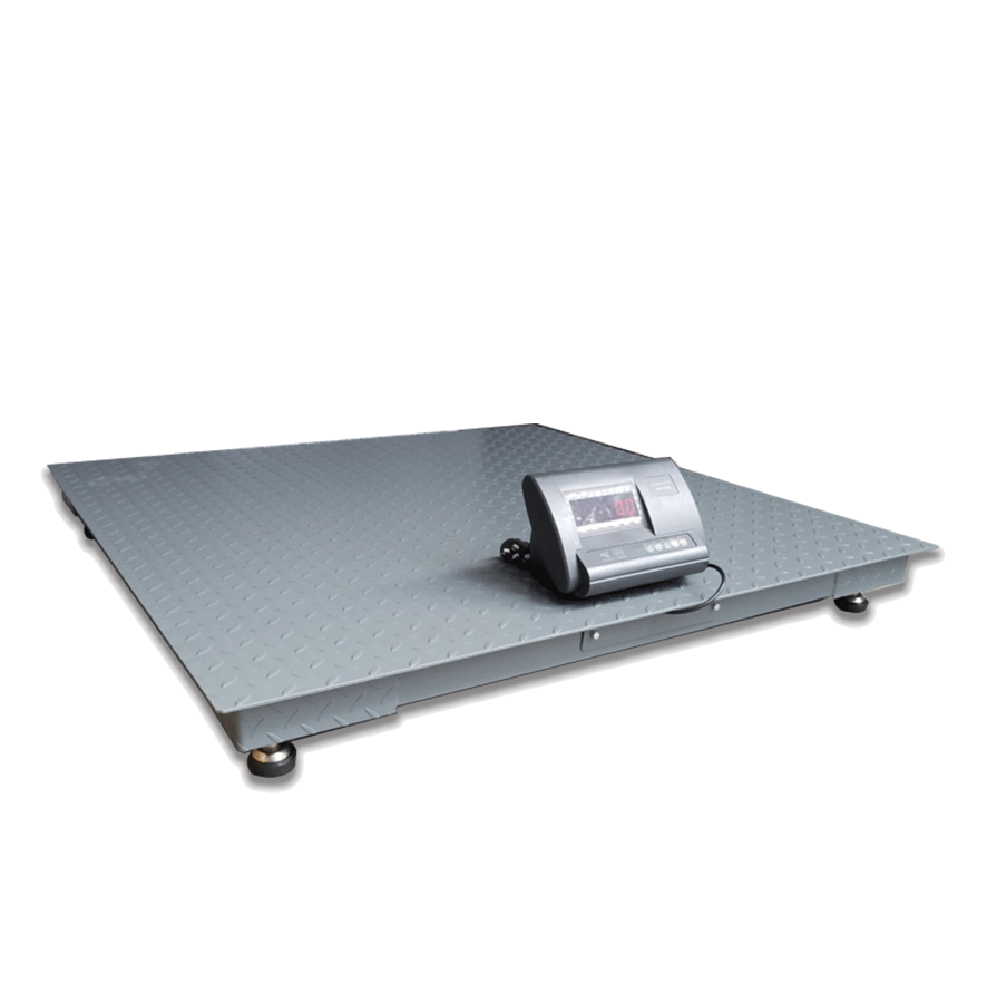

A vast selection of commercial scales are available, each developed to meet specific measurement needs across varied markets. Usual kinds include flooring scales, which are durable and appropriate for considering large products or pallets in stockrooms and distribution. Bench ranges are smaller and ideal for lighter products, usually utilized in retail settings or making for precise part control.

One more group is mobile scales, which provide the flexibility to be relocated quickly around work sites, making them ideal for area procedures or short-term setups. Accuracy scales, on the various other hand, are created for high accuracy and are often utilized in laboratories and quality assurance settings.

Load cells are critical elements in various commercial ranges, converting pressure right into an electrical signal for precise readings. In addition, truck scales offer the ways to weigh heavy vehicles and their tons, making sure conformity with regulations and enhancing logistics.

Last but not least, checkweighers automatically contrast the weight of items versus predetermined limits, enhancing quality control in assembly line (Industrial Scales). Each kind of industrial range offers a distinct feature, satisfying the certain demands of industries such as production, logistics, food processing, and pharmaceuticals

Benefits of Making Use Of Industrial Scales

Regularly making use of industrial ranges supplies considerable benefits throughout numerous markets. One of the main advantages is enhanced precision in weight measurement, which is essential for maintaining top quality criteria and regulative conformity. Exact measurements prevent pricey errors in delivery, supply, and manufacturing administration, inevitably resulting in raised functional effectiveness.

Furthermore, industrial ranges are made for toughness and toughness, permitting them to stand up to rough settings commonly found in production and warehousing. This durability guarantees a long life expectancy, lowering the demand for regular substitutes and maintenance costs.

Furthermore, employing commercial scales improves security and lessens waste. By ensuring that products are evaluated accurately, companies can avoid overwhelming cars, which can cause crashes and penalties.

Applications Throughout Different Industries

Industrial ranges play a pivotal duty in countless sectors, consisting of production, logistics, food processing, and pharmaceuticals. In manufacturing, these ranges are essential for making certain that raw materials are determined properly, consequently keeping product top quality and uniformity (Industrial Scales). Accuracy in weight dimension straight influences manufacturing effectiveness and expense monitoring

In logistics, commercial scales promote the exact considering of shipments, which is important for adhering to shipping laws and optimizing products expenses. Exact weight data assists simplify procedures and enhances supply chain administration.

The food processing industry relies greatly on industrial ranges for conformity with health and wellness laws. They are used to consider active ingredients precisely, guaranteeing that solutions fulfill both quality standards and legal demands. This is necessary not just for customer safety yet additionally for maintaining brand stability.

Pharmaceutical business make use of industrial scales to guarantee exact dosages in medication manufacturing, where also the tiniest deviation can have considerable repercussions. Conformity with rigid governing requirements makes specific weight measurement crucial in this market.

When Choosing Ranges,## Variables to Think About.

Picking the right range for particular applications requires mindful factor to consider of numerous aspects. The ability of the scale is essential; it has to accommodate the optimum weight of the items being determined without surpassing its limits. Additionally, the readability, or smallest increment the scale can Homepage properly show, is essential for accuracy, especially in markets where weight inconsistencies can bring about significant economic losses or safety and security problems.

Ecological conditions likewise play a substantial role in scale selection. For instance, ranges used in destructive or humid environments may need specialized products to guarantee longevity. Similarly, portability might be important in certain applications, necessitating battery-operated and light-weight versions.

Conclusion

In verdict, the choice of industrial scales is critical for ensuring accurate weight dimension throughout varied markets. Their ability to supply specific readings not just enhances operational efficiency but likewise supports regulatory compliance and stock management. The adaptability and toughness of these ranges promote their application in various markets, eventually adding to cost decrease and improved item quality. Thus, investing in top notch commercial scales is important for companies intending to optimize and keep high requirements profitability.

Report this page